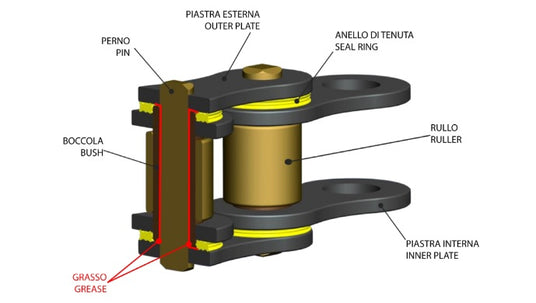

Chain components

A 120-link sealed chain is made up of 840 components:

• Pin: absorbs the weight and load of the chain. When stressed, the pin could bend, touching the

bushing: this phenomenon is called chain elongation.

• Bushing: Absorbs the load of the roller when it is in contact with the gear. This component

It acts as a “buffer”, so it must resist impacts and abrasion.

• Roller: Rotates freely against the bushing and the internal plate. Requires regular lubrication.

to reduce the effect of internal friction against the bushing and external friction against the gears.

• Plates: with the pin it absorbs the load and transmits the power.

• Sealing ring: positioned between the internal and external plate, it seals the grease contained between the pin

and bushing. To make it, special Nitrile is used that is resistant to heat, abrasion,

atmospheric agents and with a low coefficient of friction

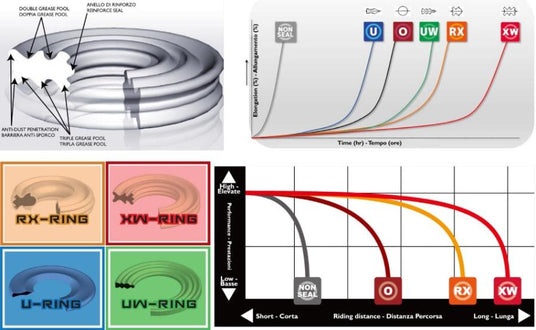

Patented RK technology

Sealed Chain Features:

• Minimum life 3 times longer than a non-sealed chain

• It does not undergo elongation until the end of its life thus avoiding the possibility of a

Imperfect coupling with pinion and crown which would cause a loss of power

• Prevents dirt from entering inside, ensuring greater durability and consistency

performance

All RK sealing rings have a design with multiple lubrication zones called Grease Pools.

As the chain heats up and the grease melts, the contact surfaces are lubricated.

and better performance is achieved thanks to the reduction of friction.

Colors & Features

Maintenance

Helpful tips for a top-quality product